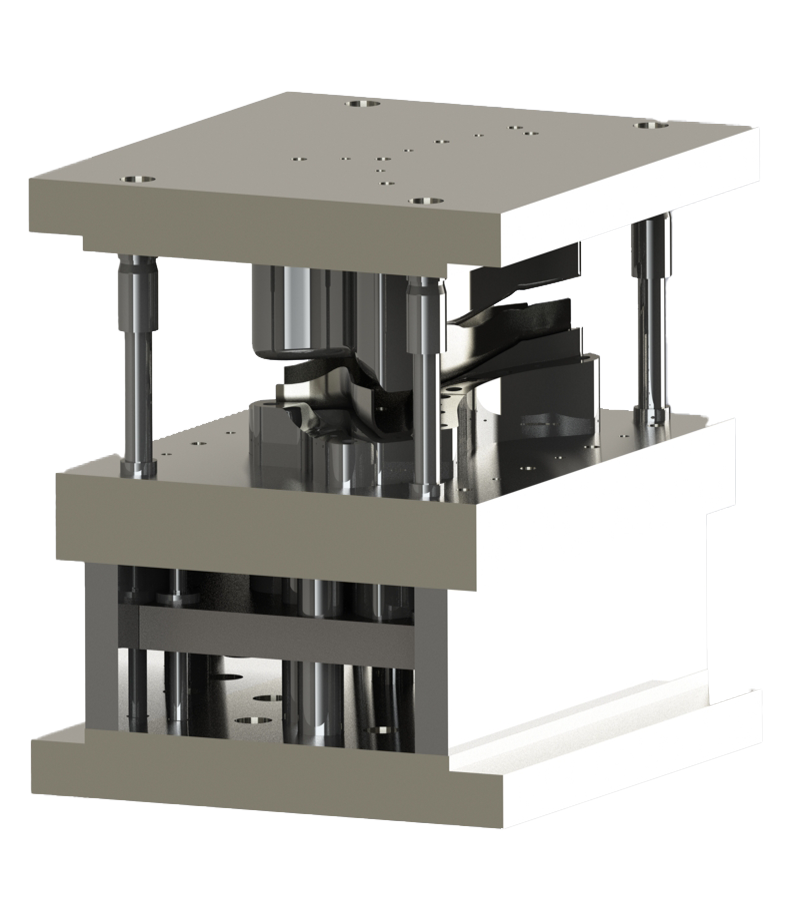

- MOLD MANUFACTURE

- PRESS PRESSURE MANUFACTURING

The journey to Perfection in mold with VARKAL

"Mold design and manufacturing is critical to manufacturing processes; proper design and management improves production efficiency and product quality."

Perfection

Excellence in Customer Satisfaction: Meet the Varkal Mold Difference

Working in harmony

Pioneer in Quality, Your Confident Companion: Varkal Mold

Guaranteed Service

Varkal Mold's Signature in Reliable Service

- Hakkımızda

VARKAL Mold

With its approximately 40-year Quality and Technology Experiences and Knowledge

Our company which is a leading company in its sector with its approximately 40-year occupational and technical knowledge and experiences continues its activities under the title of VARKAL Kalıp Otomotiv Yedek Parça Makine Demir Çelik San. ve Tic. Ltd. Şti.

Design & Manufacturing

Not only the domestic markets but also the international markets know that the mold design and manufacturing activities are critically important for the product manufacturing processes. Such factors in the mold manufacturing process of a product as mold design, time cost, personnel cost and rawmaterial cost increase the production efficiency and product quality by adding a plus value to the companies.

Quality First!

VARKAL ,adopting the principle of “PUTTING THE QUALITY FIRST”, aims at increasing the customer satisfaction to the highest levels by uniting its technical knowledge, experiences, technological developments, experienced staff & specialists and Re&De works. The company adopting the customer satisfaction as a principle takes sound steps for its activities by forming its design, manufacturing, production, quality and personnel policies in compliance with those basic principles.

Years of experience

1

+

Our Services

- Press Workshop Machine Park

- 250 ton Hydraulic Press

- 150 ton Hydraulic Press

- 120 ton Hydraulic Press

- 100 ton Hydraulic Press

- 50 ton Hydraulic Press

- 250 ton Eccentric Press

- 200 ton Eccentric Press

- 120 ton Eccentric Press

- 100 ton Eccentric Press

- 100 ton Eccentric Press

- 60 ton Eccentric Press

- 30 ton Eccentric Press

- 30 ton Eccentric Press

- Spot Welding Machines

- İşlem Teknikleri

Sheet Metal Cutting and Plastering Mold Activities: Precise Manufacturing and Forming Techniques

Metal sheet cutting and plastering mold activities are important manufacturing techniques used for metal sheet cutting and forming. These activities are crucial for specialization, forming and processing the metal parts used in the industrial production processes.

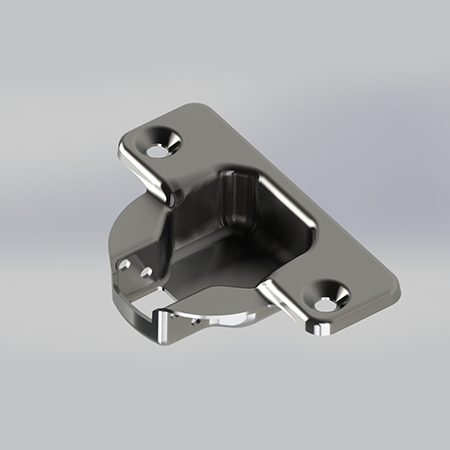

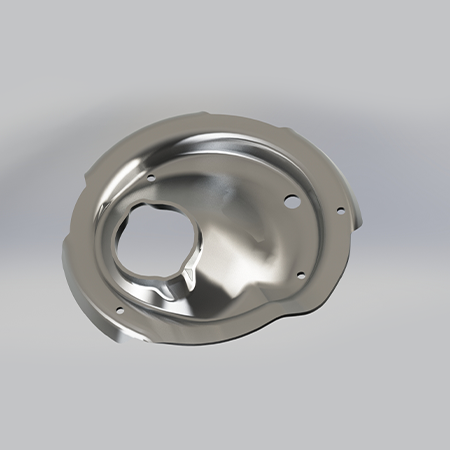

Metal Sheet Cutting Activity

Metal sheet cutting activity is a production method ensuring that the metal plates are cut in specific dimensions. This activity is generally performed such techniques as laser cutting, plasma cutting or water jet cutting. As costs of these production types are high molds are required and cutting activity is commonly used to produce products requiring precise measurements and sharp contours. The smallest details are paid attention in the production process and finally metal parts which are cut with high precision are obtained.

Plastering Mold Activity

Plastering mold activity is a technique which is used for forming and bending the metal plates or strips in a specific mold. This activity is preferred for the products especially requiring complicated, precise and esthetical shapes. Metal plates are inserted into the plastering molds and the intended shape is obtained by applying the pressing or bending activity. With this method, it is possible to form geometrical shapes which are bended in different angles and complicated styles.

Application Areas

Sheet metal cutting and plastering mold activities have a wide spectrum application areas ranging from automotive industry to whiteware and from construction materials to electronical products. Carbodies, metal coating plates, utilities parts, industrial vaults and many products are produced with this method.

Why are Metal Sheet Cutting and Plastering Mold Activities used?

Metal sheet cutting and plastering mold activities provide great advantages for forming and processing the metal materials. Parts produced with precise measurements ensure excellent conformity and high quality. These activities increase efficiency by providing time and cost savings in the production processes. At the same time it ensures that specialized designs and unique shapes are obtained.

Sonuç olarak, sac kesme ve sıvama kalıp işlemleri, endüstriyel üretimde yaratıcılığı, hassasiyeti ve verimliliği bir araya getiren kritik yöntemlerdir. Bu teknikler sayesinde, metal levhalar ve şeritler, istenen şekil ve boyutlarda kesilerek ve şekillendirilerek, farklı sektörlerde kullanılan birçok ürünün temel bileşenlerine dönüşür.

Finally metal sheet cutting and plastering mold activities are critical methods which combine creativity, precision and efficiency in the industrial production. Thanks to these techniques, metal plates and strips turns into basic components of various products used in different sectors after they are cut and formed in intended shapes and dimensions.

Sonuç olarak, sac kesme ve sıvama kalıp işlemleri, endüstriyel üretimde yaratıcılığı, hassasiyeti ve verimliliği bir araya getiren kritik yöntemlerdir. Bu teknikler sayesinde, metal levhalar ve şeritler, istenen şekil ve boyutlarda kesilerek ve şekillendirilerek, farklı sektörlerde kullanılan birçok ürünün temel bileşenlerine dönüşür.

Finally metal sheet cutting and plastering mold activities are critical methods which combine creativity, precision and efficiency in the industrial production. Thanks to these techniques, metal plates and strips turns into basic components of various products used in different sectors after they are cut and formed in intended shapes and dimensions.

Our References