About Us

VARKAL -

With its approximately 40-year Quality and Technology Experiences and Knowledge

Our company which is a leading company in its sector with its approximately 40-year occupational and technical knowledge and experiences continues its activities under the title of VARKAL Kalıp Otomotiv Yedek Parça Makine Demir Çelik San. ve Tic. Ltd. Şti.

Not only the domestic markets but also the international markets know that the mold design and manufacturing activities are critically important for the product manufacturing processes. Such factors in the mold manufacturing process of a product as mold design, time cost, personnel cost and rawmaterial cost increase the production efficiency and product quality by adding a plus value to the companies.

Quality First

VARKAL ,adopting the principle of “PUTTING THE QUALITY FIRST”, aims at increasing the customer satisfaction to the highest levels by uniting its technical knowledge, experiences, technological developments, experienced staff & specialists and Re&De works. The company adopting the customer satisfaction as a principle takes sound steps for its activities by forming its design, manufacturing, production, quality and personnel policies in compliance with those basic principles.

VARKAL is a company which makes no compromises from its quality principles. It is proud of increasing customer satisfaction to the highest level by continuously developing technical knowledge and experienced staff & specialists thanks to the designs and systematic products which it has supplied to the companies of its solutions partners.

Our Mission

To increase the customer satisfaction to the highest level and to support this objective with our quaity standards, In compliance our quality service concept we will continue to add values to our customers and strengthen our leadership in our sector.

Our Vision

To improve our production processes continuously by closely following the technological developments, to maintain our leadership in the mold design and manufacturing with our experienced staff & specialists and Re&De works,

Varkal Kalıp

As Varkal Kalıp, we are proud of rendering the highest quality services to our customers. We aim at exceed the customer expectations with our professional staff, high technology equipments and quality standards which we meticulously follow. We give priority to ensure excellence and reliability by focusing on the quality in each step.

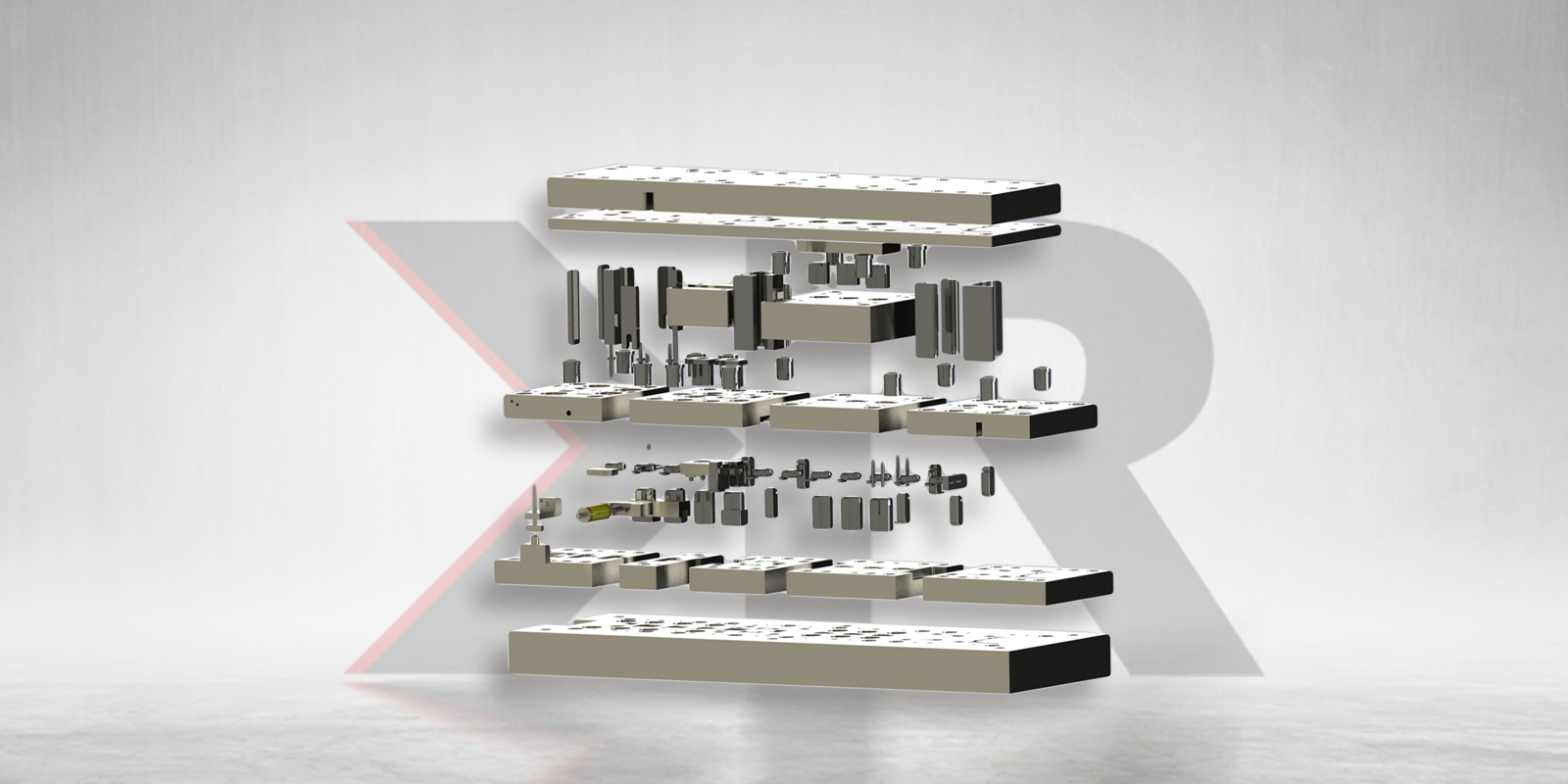

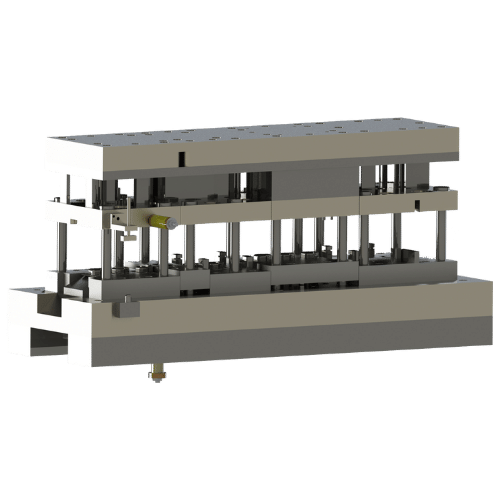

Tandem Molds

Tandem molds are systems which are composed of combining two or more mold unites operating consecutively. These molds are used with the aim of providing higher speed, more precision and more efficiency during the metal plate processing and forming. Each units is optimized to conduct different activities and accelerate the process by operating consecutively.

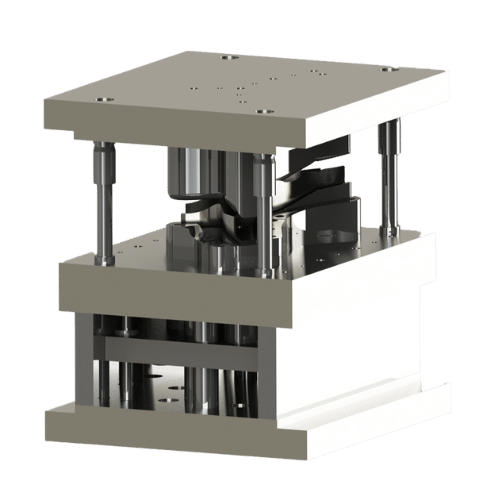

Progressive Molds

Progressive mold is a mold system which is composed of more than one units which follow each other and include different activities. Metal plates are subjected to different activities in each station by passing through the different stations on the molds. Among these activities there may be steps like cutting, bending, drilling and forming etc. Each station on the mold conducts a specific step for ensuring the intended final product. Progressive molds reduce the number of staff and machines and also increase the daily production when they are compared to the tandem molds.

Our References